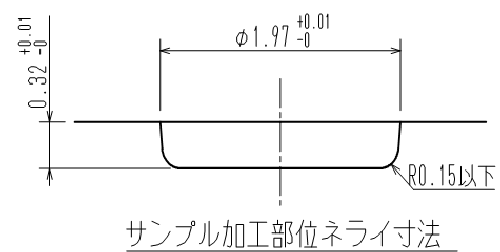

・Work material : Ultra fine Tungsten Carbide G5, G6

・Process machine, Micro Precision Process machine (No electrical discharge process).

・Mirror finish by Lap-less.

Bottom surface roughness :Ra0.05μm(same as lapping finish)

Difference to traditional process

1.Largely shorten a process time and 24 hours continuous process.

Process time of one pieceTraditional process:

Sinker electrical discharge machining + electrode Production + lapping

= 50 minutes

Tokyo Byora process

Direct carving =15 minutes.

2.Achieved a big cost down

Running cost becomes 1/5~1/10 in comparison with traditional process.

3.Realized a quality improvement.

No micro crack nor hardened layer like electrical discharge.

Maximum potential of Tungsten carbide can be utilized.

Thai

Thai 日本語

日本語

Reproduction of Die

Reproduction of Die